Trusted Electrical Transformer Manufacturers

At CHBEB, we take pride in supplying our clients with world-class and high-quality standard and custom-made transformers.

Tansformer in CHBEB

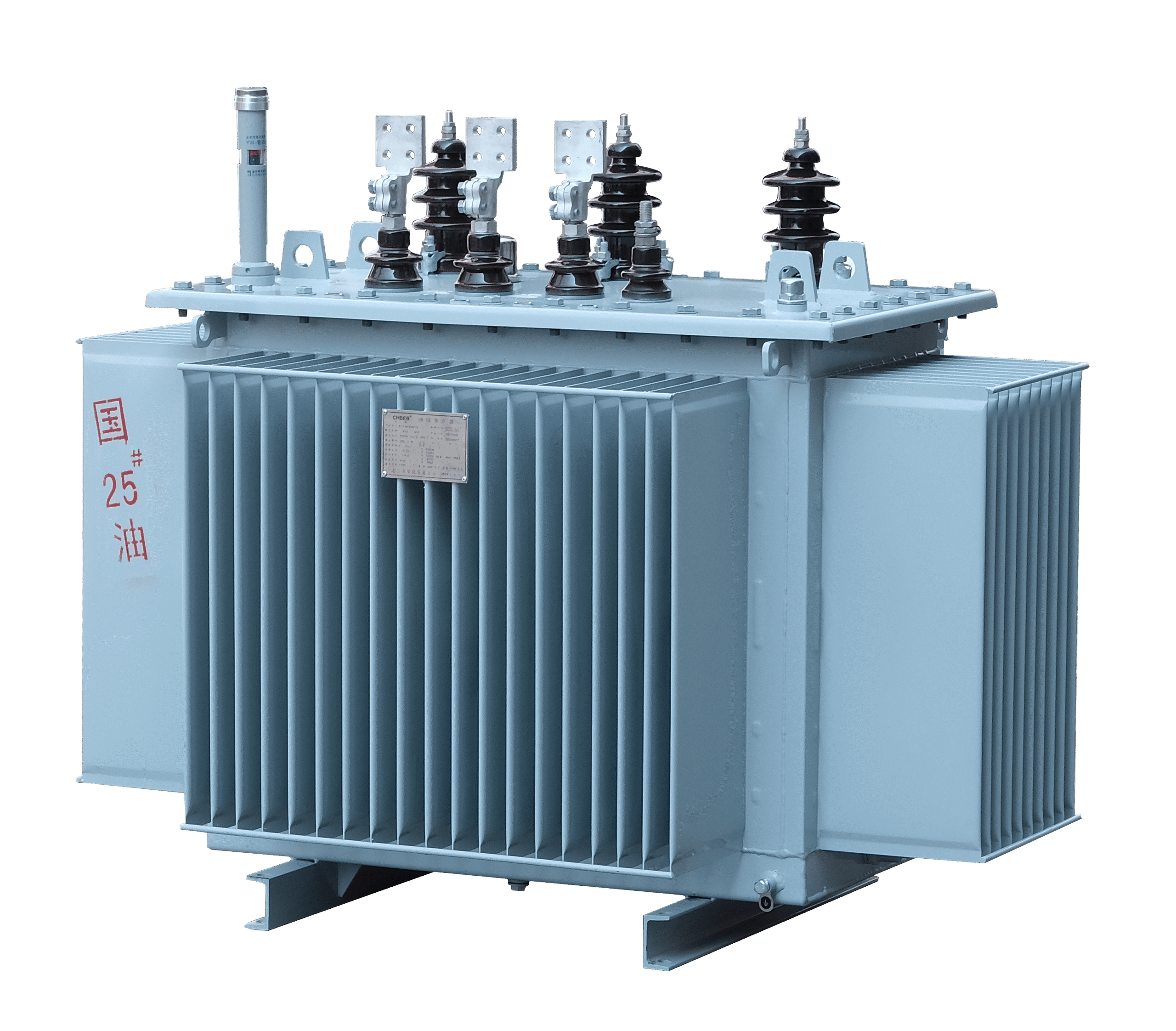

distribution transformer

High-efficiency distribution transformers for MV-to-LV step-down (11kV/0.4kV). Low-loss core design delivers stable voltage, cooler operation, and reliable service across utility feeders worldwide today safely.

Pad Mounted Transformer

Pad-mounted transformers with tamper-resistant enclosures for underground distribution. Bottom-entry cabling, safe public operation, and dependable performance for campuses and urban streets all year round.

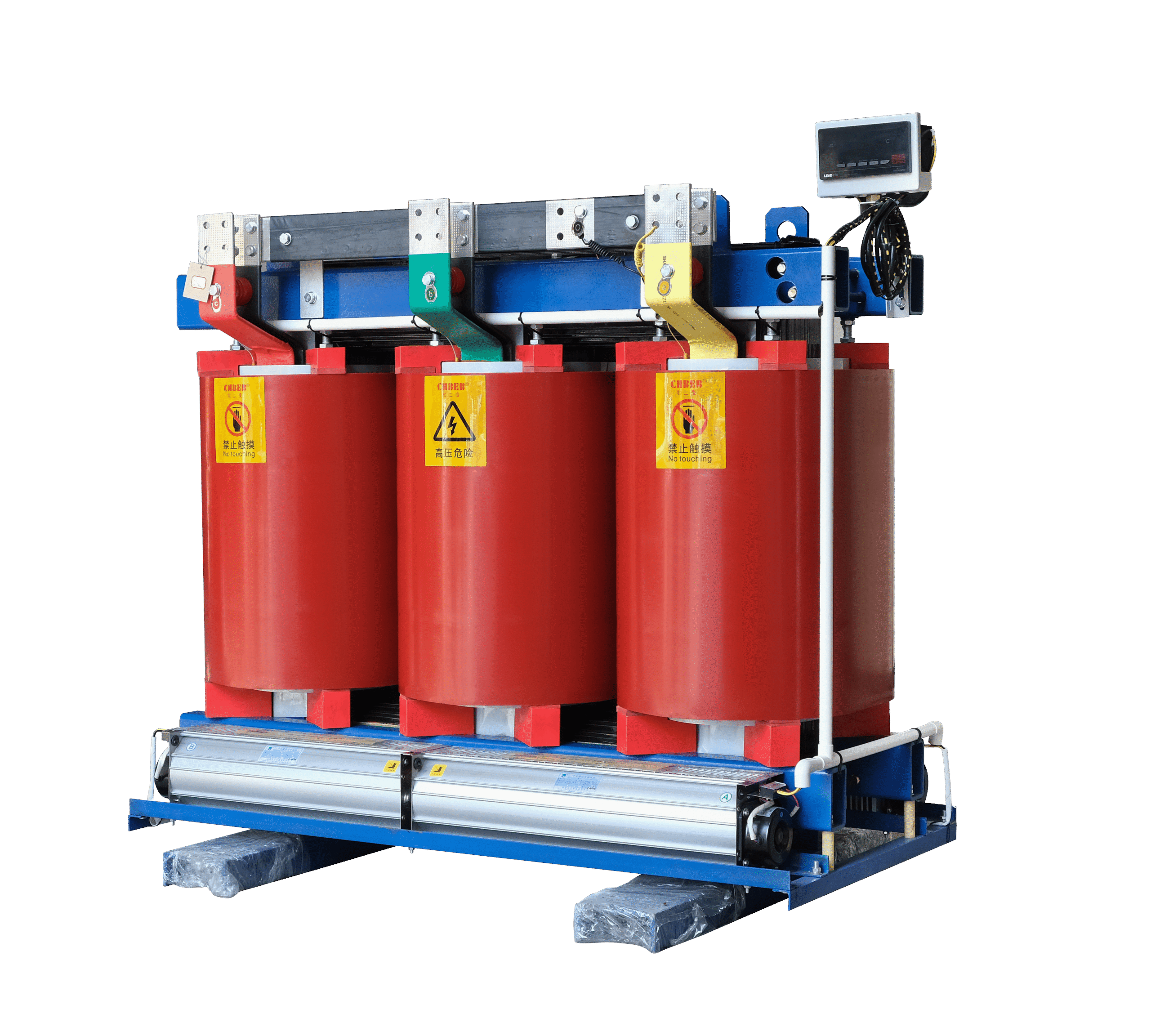

dry type transformer

Cast-resin dry type transformers for indoor distribution. Fire-resistant insulation, low partial discharge, and minimal maintenance—ideal for malls, data centers, and hazardous sites without leaks.

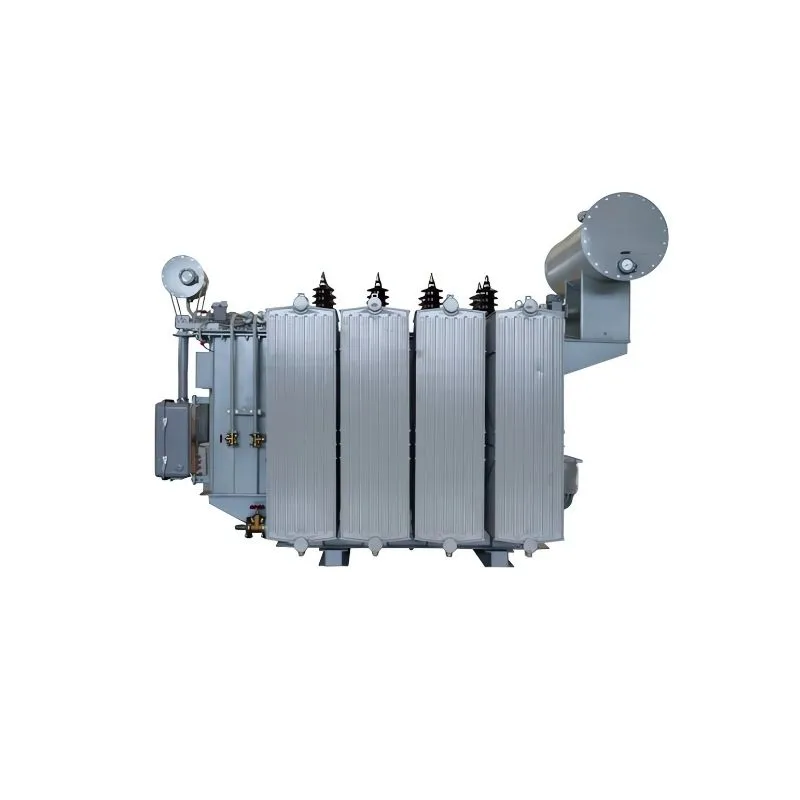

substation transformer

Rugged substation transformers for HV networks and centralized utility stations. Designed for stable voltage regulation, low losses, and long service life with proven performance under continuous heavy-duty operation.

Prefabricated & Package Substations

Factory-tested compact/kiosk substations integrating MV switchgear, transformer & LV panels for fast deployment on renewables, industry, and urban sites.

Pole Mounted Transformer

Compact pole-mounted transformers optimized for aerial installation on utility poles. Configurable for IEC or ANSI/IEEE requirements, delivering reliable overhead distribution for rural, suburban, and remote networks.

Want to see how our transformers are made? Visit our About page to explore our factory, workshop lines, and QC system.

Transformer Manufacturing Process

1. Requirement & Design

Confirm specs, drawings, and standards for your application.

2. Material Procurement + IQC

Source key materials and verify them through incoming inspection.

3. Core Cutting & Stacking

Cut and assemble the core to control loss, noise, and stability.

4. Coil Winding & Lead Welding

Wind HV/LV coils, press, and weld leads for secure connections.

5. Vacuum Drying & Insulation Prep

Remove moisture and prepare insulation for stronger dielectric strength.

6. Active Part Assembly

Assemble core, coils, and bracing into the active part.

7. Tank/Enclosure Fabrication & Painting

Fabricate the tank/enclosure, check tightness, and apply coating.

8. Final Assembly

Install accessories, cooling parts, protections, and nameplate.

9. Routine Test (IEC/ANSI)

Verify ratio, losses, impedance, and withstand performance.

10. Packing & Delivery

Pack with moisture/shock protection and arrange shipment.

Globally Recognized Quality Certifications

Why Choose CHBEB as Your Transformer Supplier

Manufacturing Expertise

We build oil-immersed, dry-type, and pad-mounted transformers with stable capacity from our Nanjing and Yueqing production parks. Decades of manufacturing heritage, standardized processes, and efficient workflows help ensure reliable quality and dependable delivery for global utility and industrial projects.

Beijing R&D Support

Our Beijing headquarters focuses on R&D and engineering support. From spec confirmation to drawings and design optimization, we respond quickly to project conditions and IEC/ANSI requirements. This helps EPC and utility clients reduce approval time, avoid rework, and move projects forward with confidence.

Factory-Direct Value

Factory-direct manufacturing and supply-chain control enable cost-effective solutions without compromising quality. With efficient production planning and export experience, we help clients lower total cost across procurement, delivery, and long-term operation—especially for utility, industrial, and infrastructure projects.

Certified Quality Control

Quality is built into every step—from incoming inspection (IQC) to routine testing before shipment. CHBEB holds ISO management systems, CCC, and authoritative inspection certifications, supported by multiple inventions and 120+ patents. This ensures stable performance, safety, and long service life in real projects.

CHBEB Electrical Transformer Manufacturers

transformer manufacturers

CHBEB GROUP CO., LTD. is one of the leading transformer manufacturers based in Wenzhou, China, with decades of expertise in the power industry. CHBEB specializes in designing and producing oil immersed transformers, dry type transformers, and pad mounted transformers, delivering reliable solutions for various industrial and commercial applications.

We serve sectors such as Power Generation, Renewable Energy, Industrial Manufacturing, Oil & Gas, Infrastructure, and Utilities. Our extensive range of transformers is engineered for efficient power distribution and energy management across diverse environments.

Our expertise lies in continuous innovation, adherence to international standards and certifications, and prompt delivery schedules, positioning us as a trusted partner among global transformer manufacturers.

Ask Us about Our Products

At CHBEB, we offer a wide range of transformer models. Request a free quote from us today!

Featured Products

Industries That We Serve

As one of the leading transformer manufacturers in China, CHBEB has been serving various market sectors where reliable power distribution plays a critical role. These industries demand high-quality transformers which, in turn, increase the efficiency and safety of their operations.

- Power Generation Industry

- Renewable Energy Industry

- Industrial Manufacturing Industry

- Oil & Gas Industry

- Commercial and Residential Buildings

- Infrastructure and Utilities Sector

Quality Assurance Tests That We Employ

At CHBEB, every product undergoes a rigorous set of quality assurance procedures to ensure safety, performance, and durability.

Our testing processes include:

Temperature Rise Test

Lightning Impulse Test

Withstand Voltage Test

Partial Discharge Test

Load Loss and No-Load Loss Measurement

Insulation Resistance Test

Mechanical Strength and Short-Circuit Withstand Tests

All tests are conducted in accordance with national and international standards under the supervision of qualified engineers.

Our Mission

At CHBEB, our mission is to remain globally competitive in an ever-evolving power industry. We aim to be the go-to global transformer supplier, especially for transformers used in critical applications. We can achieve this through intensive research and development. We understand that this journey is a continuous one. Also, by driving innovation, we can deliver superior transformer solutions to our clients. We are utilizing advanced manufacturing technology to empower our engineers and staff to further improve our customer service. Furthermore, we strive to provide top-tier value by focusing on safety and strict quality assurance of our products.

Certified

With advanced production and testing equipment, CHBEB combines modern management techniques and innovative development strategies to deliver high-quality transformers to the global market. We have been certified under the ISO 9001 quality management system, ISO 14000 environmental management, and ISO 18000 occupational health and safety standards. Additionally, our transformers are certified by the National Transformer Quality Supervision and Inspection Center and hold the CCC certification. We also hold five invention patents and more than 120 other patents covering various aspects of transformer design and manufacturing.

We guarantee that all our products undergo strict quality control processes and comply with rigorous national and international standards. Our certifications reflect our commitment to producing transformers that meet top-tier industry requirements and ensure reliability and safety in every application.

Innovative

CHBEB is renowned for customized transformer solutions. We are committed to offering our customers state-of-the-art and highly reliable CHBEB transformers that are recognized as strong contenders and alternatives to American and European brands. Our expert team comprises highly skilled engineers and technical specialists who have undergone extensive training and hold multiple certifications, contributing to the superior quality of our work. We believe that through our high-value workforce, each bringing diverse skills and talents, we can fulfill the unique requirements of our clients. We adapt to the evolving needs of our customers by enabling our research and development team to collaborate closely with them. Through product innovation and continuous research and development, our brand has advanced to become a leading transformer manufacturer in China, serving clients worldwide. We are constantly enhancing our products through dedicated research and development efforts, and we embrace the latest technologies available in the market.

Customer Satisfaction

Our manufacturing facilities operate around the clock to supply our customers with high-quality transformers, which can be customized to meet specific project requirements. We take pride in our ability to meet production deadlines and provide clients with precisely what they need through our efficient and streamlined production processes. Our engineers and technicians are experts in their fields and are dedicated to delivering products within the agreed delivery schedules. Our focus is on customer satisfaction, and we are committed to manufacturing transformers according to the exact specifications provided by our clients. Our team understands that time is critical. When we commit to a certain timeframe, you can rest assured that we will deliver as promised.

Check out our customer testimonials below:

Transformer FAQs

In today’s tight transformer market, what is your typical lead time?

Lead time depends on rating, voltage class, IEC/ANSI requirements, and customization level. Typically, standard distribution and mid-size units are 12–20 weeks. If stock units are available, we can deliver in 2–6 weeks through a rapid retrofit program. Once we receive your key parameters, we’ll issue a practical delivery milestone plan (design → production → FAT → shipment).

How do you manage copper/steel price fluctuations to keep quotations and project budgets under control?

We offer two mechanisms: a short quotation validity (market-linked) and project price/material locking for budget control on major orders. At contract stage, we clarify the cost structure and critical material strategy to reduce budget risk from commodity volatility.

Can you manufacture transformers compliant with IEC and ANSI/IEEE standards? How do you reduce acceptance risk?

Yes. We support both IEC 60076 and ANSI/IEEE C57 systems. To reduce acceptance risk, we confirm temperature rise, insulation/BIL, losses/efficiency, short-circuit withstand, noise, and test scope in the technical agreement, and provide a compliance matrix before FAT.

What FAT (Factory Acceptance Tests) do you perform before shipment? Can overseas customers witness the tests remotely?

We perform FAT per IEC/IEEE standards, typically including ratio, winding resistance, insulation tests, applied/induced voltage tests, no-load/load losses, and impedance. Temperature rise, impulse, partial discharge, and noise tests are available upon request. We also offer remote FAT witnessing via live video, allowing you to view the procedure and readings in real time and align key points with our engineers.

If I can’t visit the factory in China, how can I verify you are a real manufacturer and ensure reliable quality?

We provide a verifiable “trust pack”: factory videos and key equipment list, production/testing process overview, reference projects (redacted if needed), management system certificates, and optional third-party audits (e.g., SGS/TÜV) upon request. We also support remote video factory audits and remote FAT witnessing to ensure transparent, traceable quality.

Transformers are heavy and oversized—how do you prevent damage during transportation?

We apply export-grade packing and lashing plans and can install shock/tilt indicators to track abnormal impacts during transit. Oil-immersed and dry-type units use different moisture-proof and reinforcement methods (e.g., nitrogen/filled-oil options, vacuum moisture-proof packing—project-dependent). We also provide packing and lashing photo records for receiving inspection.

Blogs About Transformer Manufacturers

Choosing the wrong transformer causes project failures and high costs. Understanding their core differences is key to making the right choice for your power system’s

In-Depth Engineering: How Pad-Mounted Transformers Master the Heat Challenge Introduction In residential, business, and utility networks, pad-mounted transformers function quietly, but they are always combating

China Power Transformer Market Survey: Sourcing HV Capabilities and International OEM Solutions Introduction It can be hard to buy high-voltage transformers from China since there